- PRODUCT

- Site > Home > Sintered Wire Mesh > Sintered Wire Mesh

- Product images

- Detailed description

Sintered Wire Mesh with excellent mechanical properties for purification and filtration

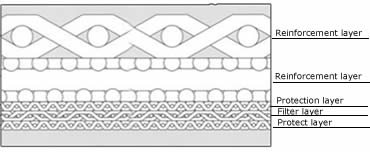

5 Layer Sintered Wire Mesh Structure Drawing Picture

Sintered wire mesh is made form multiple layers of woven wire mesh panel together using a sintering process. This process combines heat and pressure to permanently bond multi-layers of mesh together. The same physical process used to fuse individual wires together within a layer of wire mesh is also be used to fuse adjacent layers of mesh together. This creates a unique material offering excellent mechanical properties. It is ideal material for purification and filtration. It may be from 5, 6 or 7 layers of wire mesh (5 layers sintered filter mesh structure drawing as top picture).

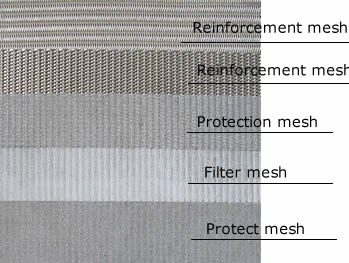

The follow picture shows a stainless steel sintered wire mesh panel made form five different layers of stainless steel wire mesh combined and sintered together through vacuum sintering, compressing, and rolling, forming a porous sinter mesh.

The cross section structure of sinter wire mesh

Specifications

Material:

Standard material SUS304 (AISI304), SUS316 (AISI316), SUS316L (AISI316L), Alloy Steel Hastelloy, Monel, and Inconel.

Standard Size:

500 × 1000mm, 600 × 1200mm, 1000 × 1000mm, 1200 × 1200mm, 300 × 1500mm.

Fabrication: easily formed, sheared, welded and punched.

The five layers of sintered wire mesh filter

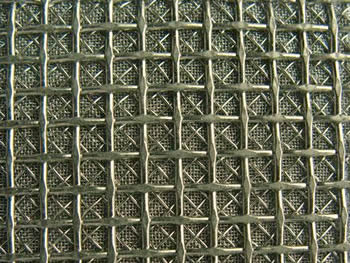

Plain woven sinter wire mesh

What types of sinter mesh filters we are supply:

1. standard combination of 5-layer sintered wire mesh

2. sintered together by many layers of plain-woven square mesh

3. sintered together by many layers of dutch-woven square mesh

4. sintered by perforated plate and multi-layer stainless steel wire mesh.

Our sintered mesh panels may be formed into filter elements such as filter discs, cartridges, cones, cylinders, and tube.

Sintered wire mesh has many advantages compare with other filter mesh, such as:

Sintered woven wire filer plates and perforated sintered tube

- * High strength and durability since high temperature sintering;

- * Anti-corrosion, and heat resistance up to 480℃;

- * Steady filter rating from the 1micron to 100 micron;

- * Filter mesh not easy to deform because of two protective layers;

- * Can used for uniform filtration in high pressure or high viscosity environment;

- * Suits for cutting, bending, punching, stretching, and welding.

Sintered wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particle, transpiration cooling under extremity high temperature, control air flow distribution, enhancement of heat and mass transfer, noise reduction, current limitation, and wildly used in aerospace, petrochemical industry, pharmaceutical industry, environmental protection industry.

Model Nominal Filter Rating (um) Structure Protective Layer + Control Layer + Dispersion Layer + Reinforce Layer + Reinforce Layer Thickness

(mm)Air Permeability (L/min/cm2) Bubble Pressure (mm H2O) Weight (kg/m2) Porosity (%) SM5-1 1 100 + 400 × 2800 + 100 + 12 × 64 + 64 × 12 1.7 1.81 360-600 5-layer sintered wire mesh(8.4)6-layer sintered wire mesh (14.4)40% SM5-2 2 100 + 325 × 2300 + 100 + 12 × 64 + 64 × 12 1.7 2.35 300-590 SM5-5 5 100 + 200 × 1400 + 100 + 12 × 64 + 64 × 12 1.7 2.42 260-550 SM5-10 10 100 + 165 × 1400 + 100 + 12 × 64 + 64 × 12 1.7 3.00 220-500 SM5-15 15 100 + 165 × 1200 + 100 + 12 × 64 + 64 × 12 1.7 3.41 200-480 SM5-20 20 100 + 165 × 800 + 100 + 12 × 64 + 64 × 12 1.7 4.50 170-450 SM5-25 25 100 + 165 × 600 + 100 + 12 × 64 + 64 × 12 1.7 6.12 150-410 SM5-30 30 100 + 450 + 100 + 12 × 64 + 64 × 12 1.7 6.7 120-390 SM5-40 40 100 + 325 + 100 + 12 × 64 + 64 × 12 1.7 6.86 100-350 SM5-50 50 100 + 250 + 100 + 12 × 64 + 64 × 12 1.7 8.41 90-300 SM5-75 75 100 + 200 + 100 + 12 × 64 + 64 × 12 1.7 8.7 80-250 SM5-100 100 100 + 150 + 100 + 12 × 64 + 64 × 12 1.7 9.1 70-190 150 150 50 + 100 + 50 + 30 + 30 + 100 + 50 2.0 25.00 50~150 200 200 40 + 80 + 40 + 20 + 40 + 80 + 40 2.0 26.00 50~150 Note: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm. And it has the higher anti-pressure ability

- HOME | ABOUT US | PRODUCTS | Send Inquiry | CONTACT US |

- Address:33 Qinhuangxi Street, Qinhuangdao

- Tel:0086-335-3893600 Fax:0086-335-3870760

- Copyright @ 2009 - 2014 Anbao